SPECIAL BEARINGS

WORLD REKNOWNED FOR SPECIAL SIZE AND SPECIAL PROFILE BEARINGS

Special Bearings/ Non-Standard Parts

In addition to the standard range of bearings, Exalto has become known worldwide for the manufacture of special size and special profile bearings.

Special Flute Shapes

We can accommodate non-standards flute shapes and patterns such as helical flutes and annular grooves in either left or right hand spiral along with plain bore seals.

Special Profile Shells

The same level of engineering is used to machine “special” profile shells with grooves, chamfers, keyways, flanges or externally cut screw threads. We can manufacture your bearings to specification from drawing.

Re-line Service

If bearings are still in a good condition externally and are not damaged or distorted, we can offer a re-lining service. This is a less expensive and – often more important – a faster option than manufacturing a complete new bearing. We remove the old rubber lining from the existing bearing and cleanse the shell internally to allow for vulcanisation of the new lining to the surface of the metal. We then re-mould the bearing, trim it on both ends and re-grind to the correct clearances required by our customer to suit the rotating shaft diameter.

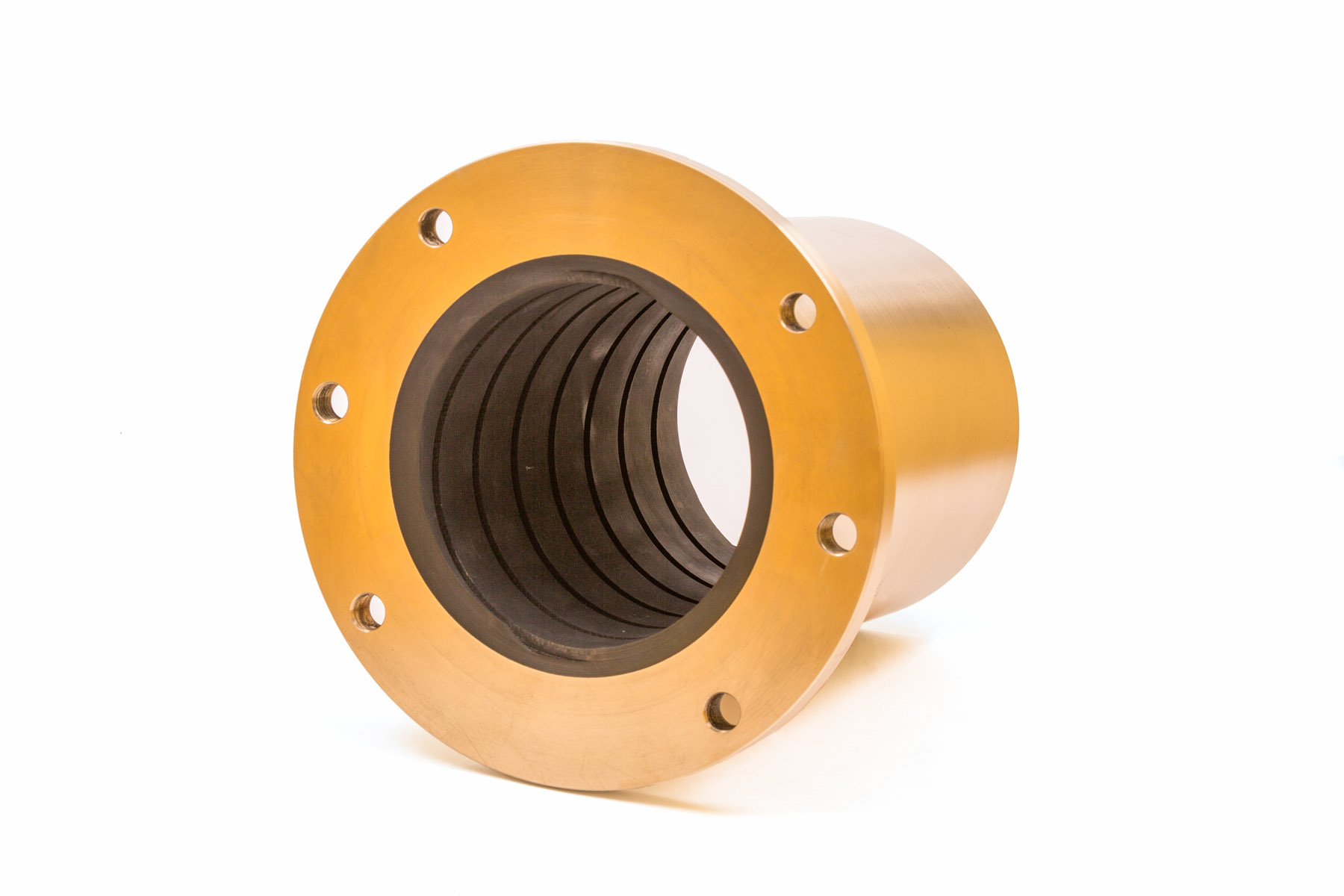

Flange Bearings

Where required for securing into a housing, flange bearings can be manufactured to specification.

Non-Standard Bearings

To enable cost-effective repairs Exalto Bearings UK Limited due to our vast amount of internal tooling options can very quickly save our customers a significant amount of money by producing bearings with either or both an oversize OD Ø Diameter or undersize ID Ø Diameter enabling them to make their equipment overhaul quicker and more economical to overhaul by skimming housing bores and turning down shaft sleeves which we can produce bearings to suit enabling tome to be saved awaiting new castings and raw materials.

Re-Lining Option

We’re always happy to help with advice and support to give our customers complete piece of mind. Plus, we can offer a comprehensive re-line service This can be cheaper and quicker than bearing replacement, and we we’ll always advise if this is your best option.

Rubberized Silicon Carbide Bearings

Exalto Bearings UK Limited can offer silicon carbide bearings with a protective vulcanized rubber coating against shock which contribute to the good working of the pumps and can be manufactured in a number of sizes to customer drawings. These bearings can assist manufacturers by adding additional mechanical strength, chemical resistance, thermal conductivity, hardness and resistance to wear.