Cutlass Bearing Installation

The following is a brief guide for replacing a cutlass bearing.

Standard Bearing Installation

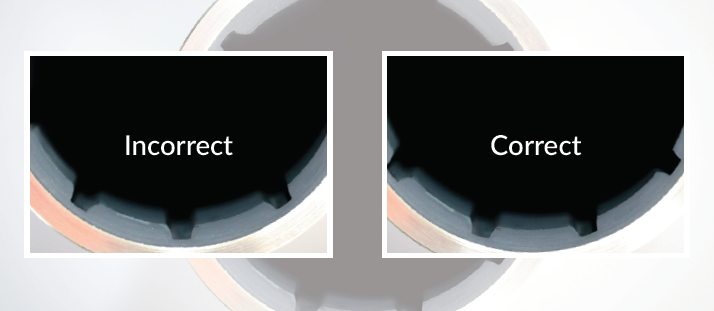

For a marine cutlass bearing to operate satisfactorily, it must be first mounted correctly within the stern tube or bracket, e.g. the bearing must be inserted with the landed area along the bottom to avoid damage on start-up.

We do not recommend fitting a Brass Bearing into a housing of dissimilar metal – in cases of a Steel or Aluminium housing, a Phenolic, GRP or other composite bearing is advised.

In marine applications, cutlass bearings are generally installed in a housing with a light press fit and held in place by either Loctite or cone point set screws to prevent it from spinning. If this is done, drill part way through the shell only. Do not lubricate the inside of the housing or the outside of the bearing shell.

Often a second setscrew is installed on top of the first to lock the first setscrew in place. The bearing shell is spotted to receive the setscrews in such a manner as to prevent them from extending through the shell into the rubber and thus forcing the rubber against the shaft. This permits the setscrew to prevent movement of the bearing without requiring the screw to be so tight that distortion of the bearing could occur.

Press Fit/Shrink Fit

Chilling sleeve and flanged bearings before fitting is an acceptable practise to achieve an interference fit between the bearing shell and housing. The method of chilling must be slow and mild in temperature (no lower than -18oC) and the interference fit light. If the chilling is fast with extreme temperature drops, the thermal shock can result in the separation of the bond between the rubber and the metal shell. Never use dry ice to cool a Cutlass Bearing. The interference fit between the outside diameter of the bearing and the inside diameter of the housing should not be more than a light press fit. Chilled bearings should be pressed into the housing, not pounded. Pounding a chilled bearing can create sufficient shock to separate or break the metal to rubber bond.

Flanged Bearings

Flanged bearings should be installed with a light press fit and secured by suitable studs and nuts through the flange.

Re-installation of the Shaft & Installation Lubricants

Use care in installing heavy shafts. In the case of large and heavy shafts, use a mild water-soluble soap on all bearings. Never use petroleum-based lubricants. Non-water-soluble lubricants can leave a residue that can restrict water flow. Glycerine is a suitable lubricant to use when installing shafts. Care must be taken to prevent tearing the rubber lining when the shaft is inserted into the bearing. The weight of the shaft should be properly supported during the process.

NB. All Exalto Bearings are precision machined in-house to suit a housing with a H7 hole, in accordance with ISO 268-2